-

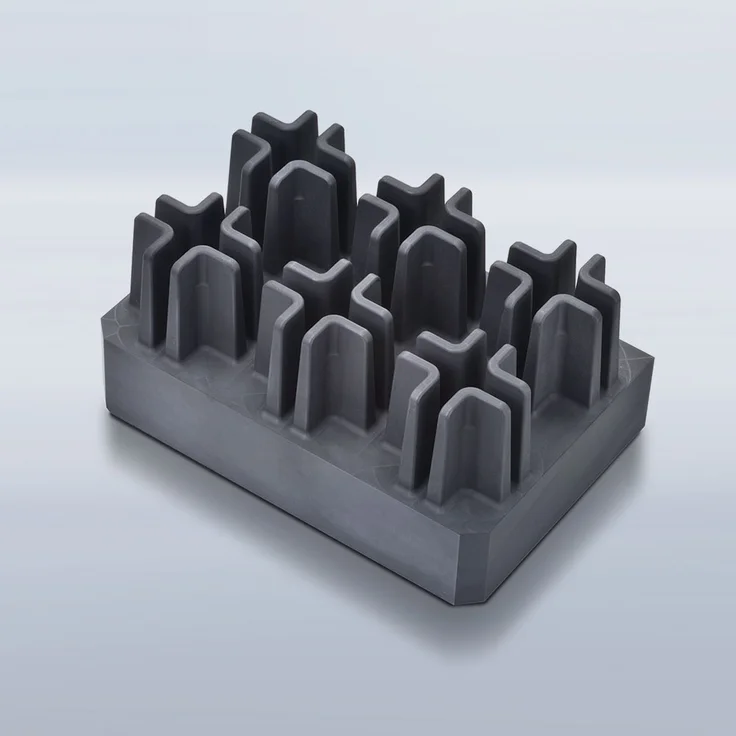

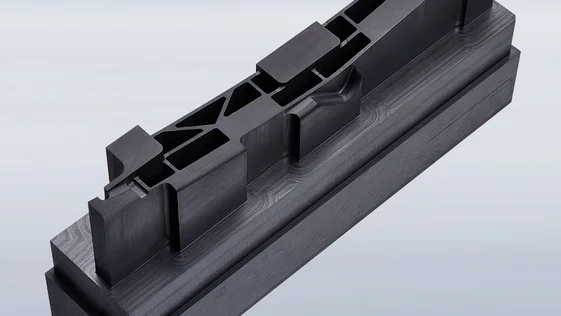

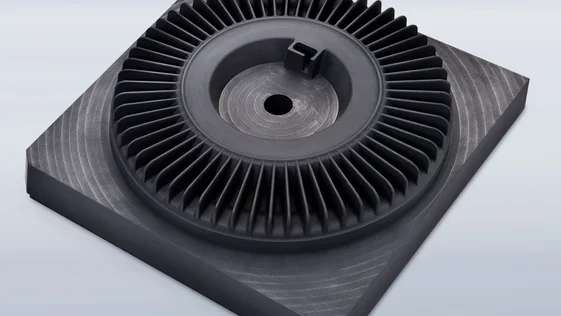

Ellor®: Blöcke und Rohlinge aus hochdichtem isotropem Graphit für Ihre Funkenerosionselektroden

Graphit für EDM

Graphit hat viele Vorteile und ist dadurch das meistverwendete Material für Funkenerosionselektroden:

- Beständigkeit gegen Temperaturschocks

- Geringer Wärmeausdehnungskoeffizienten und hervorragende geometrische Stabilität

- Bearbeitbarkeit

- Geringer Verschleiß während der Funkenbildung

Mersen ist in der Lage, für die jeweilige Kundenanforderung die beste Graphitsorte mit dem besten Qualitäts-Leistungs-Verhältnis anzubieten. -

-

Ellor® 18

Universal fine grain grade

Ein Graphit mittlerer Dichte für die Halbfeinbearbeitung und das Aufrauen in der kürzesten Zeit und zu minimalen Kosten.

-

Ellor® 20

Universal fine grain grade

A graphite for both roughing and finishing operations. Ideal for manufacturing plastic moulds.

-

Ellor® 25

Universal superfine grain grade

The greater density of this grade provides a better surface finish. Its mechanical properties enhance the service life of electrodes.

-

Ellor® 30

Exceptional superfine grain grades

The surface finish is better and electrode wear is always the lowest.

-

Ellor® 40

Exceptional superfine grain grades

The surface finish is better and electrode wear is always the lowest.

-

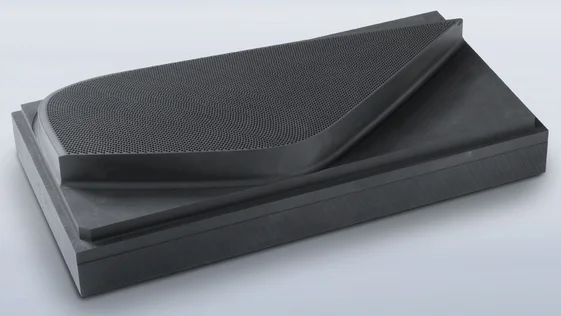

Ellor® 50

Exceptional superfine grain grades

Very fine structure and high density: very precise machining details and remarkable surface finish, whilst reducing electrode wear.

-

Ellor® DS4

The premium ultrafine grain graphite

Exceptional surface finish, outstanding strength and wear resistance.

-

-

ELLOR® isostatic graphite from Mersen has numerous advantages, making it the preferred material being used for die-sink electrodes.

- It is easy to machine.

- It is very resistant to thermal shock.

- It has a low coefficient of thermal expansion (3 times lower than copper) which guarantees stability of electrode geometry during EDM.

- It does not melt, but goes directly from the solid state to the gaseous at 3400°C, which reduces wear.

- Its density is 5 times lower than that of copper, which results in lighter electrodes.

- It provides a higher metal removal rate than copper with less wear.

- It has the unique characteristic that the wear ratio tends to decrease as the peak current increases.

-

-

Product Literature

Technische Dokumentation

Ellor® Graphite Grades for Electrical Discharge Machining (EDM)

pdf - 4.35 MB | 8. Juli 2020

Dokumentation